2277 Longyang Rd. Pudong, Shanghai, China info@mixingchina.com

Tracked Mobile Jaw Crusher

- You are currently here!

- Home Product Aggregate Treatment Equipment Tracked Mobile Jaw Crusher

Tracked Mobile Jaw Crusher

NFLG tracked mobile jaw crusher NFJ1480E is applied in Hebei, China

- Location: Hebei, China

- Model: NFJ1480E

- Startup: 2015

- Equipment highlights: Stable performance, energy saving, convenient transition

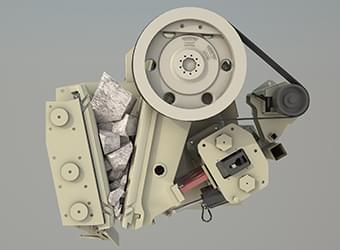

Tracked Mobile Jaw Crusher

Introduction& Advantages

The NFLG crawler mobile crushing station has the characteristics of high reliability, large crushing ratio, intelligent control, excellent productivity, compact structure, convenient transportation and maintenance, etc., making it the best choice for mine crushing, sand and stone aggregate processing, solid waste recovery and reuse.

- NFLG tracked mobile jaw crushing station, the technology comes from international first-class mobile crushing screening technology, through 8 years of joint venture, technology transformation, now, NFLG has fully mastered crawler hydraulic mobile crushing screening technology.

- The core components adopt international first-tier brands such as Linde, Eaton of the United States, and IFM of Germany. The imported components of the whole machine occupy more than 78%, and the quality is more guaranteed.

Parameters

| Model | NFJ1060 | NFJ1175 | NFJ1175 | NFJ1175E | NFJ1480E |

|---|---|---|---|---|---|

| Scope of application | Primary crushing for aggregate treatment, solid waste treatment, mining, etc. | ||||

| Crusher model | JW1060 | JW1175 | JW1480 | JW1175E | JW1480E |

| Driving mode | Hydrostatic Drive | Motor drive with frequency converter | |||

| Maximum feed size(mm) | 550 | 650 | 700 | 650 | 700 |

| Crusher speed(rpm) | 220-290 | 225-265 | 230-280 | 225-260 | |

| Engine type/power(kW) | CAT C9/224 | CAT C9/261 | CAT C13/328 | Perkins 1104/74.5 | Cummins QSB 6.7/129 |

| Engine speed(rpm) | 2000 | 1900 | 1800 | 2200 | |

| Pre-screening configuration | Integrated pre-screening | Integrated pre-screening | Integrated pre-screening | Independent pre-screening | |

| Receiving hopper capacity(m³) | 5 | 9 | 10 | 9 | 10 |

| Expanded hopper capacity (m³) optional | 8 | N/A | 12 | N/A | 12 |

| Maximum capacity(mtph) | 350 | 475 | 750 | 475 | 750 |

| Weight (t) (excluding side belt and iron remover) | 34.74 | 51.3 | 75.2 | 50 | 81 |

| Transportation dimension L×W×H(m) | 14.1×2.6×3.4 | 14.5×2.9×3.5 | 18×3.5×3.8 | 14.5×2.9×3.5 | 18×3.4×3.8 |

| WorKing dimension L×W×H(m) | 14.1×5.8×3.5 | 15.7×6.2×4 | 20.7×6.7×4.6 | 15.7×6.2×4 | 20.6×7.4×5.1 |

Receiving hopper

Sub TitleHydraulically folded hopper side plate; High wear resistant steel plate.

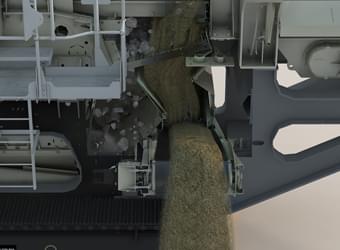

Vibrating feeder with grid section

Sub TitleThrough the variable speed control feeder, raw materials are continuously fed to the crusher; Double layer vibrating feeder, effectively screen fine materials and impurities. The top layer is a heavy duty vibrating grate, and the bottom layer is a mesh screen or rubber plate. The raw materials under the sieve can be selectively transported to the main belt conveyor or side belt conveyor through the hopper. Improve crushing feeding effect, reduce blocking and overflow; The mesh is easy to replace.

Crusher

Sub TitleStrong power, high reliability, and long stroke. High strength fabricated structure. The pressure sensor of main engine can detect the load to ensure continuous feeding. Hydraulic regulating discharge port. High wear-resistant jaw plate, long service life, easy maintenance, convenient replacement.

Steel bar deflection plate and main conveyor

Sub TitleTo prevent the steel bar from piercing the belt. Folding for transport. Tear resistant belt; high strength scraper is installed at the head drum. Equipped with water spraying and dust collecting device.

Chassis

Sub TitleA solid frame with all welded beams and columns. Easy to maintenance and clean. Evenly distributed weight ensures excellent performance.

Control system

Sub TitleDouble deck cabinet body, vibration isolation, waterproof, dustproof and anti-moisture. Simplified, logical, and control system is easy to operate.

Crawler

Sub TitleUsing a sturdy tracked chassis, which can work in a harsh environment. Bolt lock, two speed adjustable, with "soft start" (NFJ1175 only).

Magnetic separator(optional)

Sub TitleHigh sorting capacity iron remover, automatic removal of metal impurities, protection of subordinate equipment.

Side belt conveyor (optional)

Sub TitleWith polyurethane scraper to remove sludge.