2277 Longyang Rd. Pudong, Shanghai, China info@mixingchina.com

Tracked Mobile Screen

- You are currently here!

- Home Product Aggregate Treatment Equipment Tracked Mobile Screen

Tracked Mobile Screen

Stable performance, energy saving, convenient transition

- Location: Shandong, China

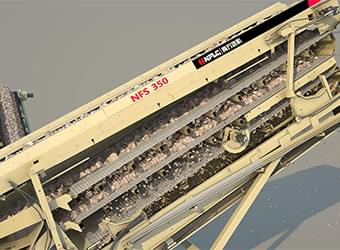

- Model: NFI1111 + NFS350

- Startup: 2017

- Equipment highlights: Stable performance, energy saving, convenient transition

Tracked Mobile Screen

Introduction& Advantages

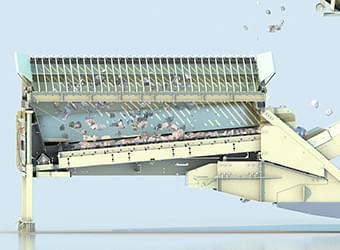

NFLG crawler mobile screen, using all diesel engine power, hydraulic drive technology, the main core parts are: the engine (caterpillar), hydraulic, bearing, valve group and other fully follow the imported brand. Crawler mobile screening station can be used in quarry, mine, construction demolition debris treatment, topsoil treatment, material recycling, sand and gravel screening, coal mine and aggregate screening.

- Use the international first-class brand caterpillar engine, strong power, efficient and stable performance, easy to maintain and clean.

- The core components adopt international first-tier brands such as Linde, Eaton of the United States, and IFM of Germany. The imported components of the whole machine occupy more than 78%, and the quality is more guaranteed.

Parameters

| Model | NFS350 | NFS350E | NFS550 |

|---|---|---|---|

| Scope of application | It is used for separating broken sand aggregate and gravel aggregate and recycling. | It is used for heavy screening, blasting or breaking rock, river gravel, construction and demolition waste, recycling applications. | |

| Maximum throughput(tph) | 500 | ||

| Maximum feed size(mm) | 150 | 500 | |

| The layer numbers of screen box | Double bearing high performance three – layers circular vibrating screen | Double bearing high performance heavy duty double layers vibrating screen | |

| Double bearing high performance heavy duty double layers vibrating screen | 18°-30° | 13°-19° | |

| Engine type/power(kW) | CAT C4.4 97kW | CAT4.4 97kW(bi-motor):2*37 | CAT4.4 83kW |

| Weight (t) | 38.5 | 40 | 32 |

| Transportation dimension L×W×H(m) | 19.3×3×3.6 | 14.7×3×3.4 | |

Feeder

Belt width 1200mm variable speed belt feeder. Single layer fixed grizzly (optional).Double layers vibrating grate sieve (optional).

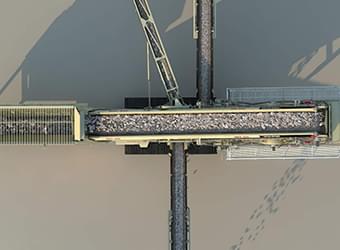

Main belt conveyor

The super-wide main belt conveyor ensures the efficient utilization of the screen surface and ensures the output.

Three layers sieve box

The screen area is 9.3㎡,and the screen angle can be adjusted to ensure the distribution of materials on the screen surface and improve the screening efficiency.

Fine material belt conveyor

Super wide fine material belt conveyor ensures efficient conveying and no overflow.

Coarse material belt conveyor

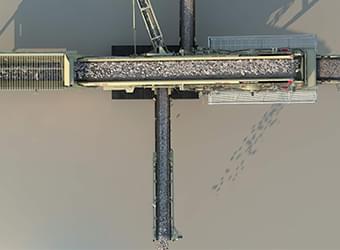

Hydraulically foldable; increased the stacking height and reduced the number of times of transfer.

Medium size material belt conveyor

Combination of rollers at different angles to prevent overflow. And it can be hydraulically folded.

Oversize material belt conveyor

It has 0-75° to form a cage type crushing and screening production line. Increase the stacking height, reduce the number of times of transfer.

Control system

Double deck cabinet body and inspection door system to protect dust and moisture effectively. Imported vehicle controller and dialog processing module control; high standard wiring harness manufacturing process to ensure stable and lasting operation of the system. Simplify equipment fault diagnosis with code and icon instructions, and real-time monitoring of engine information is conducive to on-site maintenance and diagnosis.

Framework

Rugged tracked chassis for harsh working conditions.