2277 Longyang Rd. Pudong, Shanghai, China info@mixingchina.com

RLB asphalt plant mix hot recycling

- You are currently here!

- Home Product Asphalt Mixing Plant RLB asphalt plant mix hot recycling

RLB asphalt plant mix hot recycling

NFLG GLB3000 asphalt mixing plant of bottom-mounted HMA storage compartment and RLB1750 hot RAP recycling plant used in Malaysia

- Location: Kuala Lumpur, Malaysia

- Model: GLB3000+ RLB1750

- Startup: 2018

- Equipment highlights: Environmental protection and energy conservation, production efficiency

RLB asphalt plant mix hot recycling

Introduction& Advantages

NFLG RAP hot recycling plant is to recycle the milled RAP from the road. Through screening, heating, storage and weighing, the batch with specific composition is added to the mixer by fully mixing with the new asphalt for the qualified HMA. NFLG meets client’s need for RAP production to gain more economic margin by upgrading the current facility with one new modular block of RAP production unit. The plant is applied in the projects of road of all grades, expressway, municipal roads and etc.

- Modular design, less space occupied, easy installation.

- Higher recycled rate for cost competence.

Parameters

| Model | RLB1000 | RLB1750 | RLB2000 | RLB2500 |

| Rated output | 60-80t/h | 110-130t/h | 140-160t/h | 180-200t/h |

| Cold bin | 2×9 m³ | |||

| Capacity of weighing bin | 1m³ | 1.2m³ | 1.5m³ | 2m³ |

| Matched model of raw material machine | 2000 | 3000 | 4000 | 5000 |

| Standard installed power | 170kW | 209kW | 249kW | 277kW |

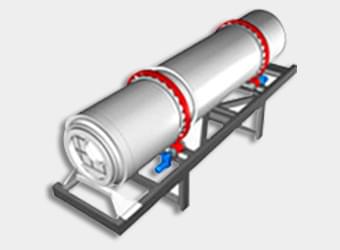

RAP dryer system

high thermal efficiency, less energy consumedEuropean primary technology, improve thermal efficiency. No heating chamber to reduce maintenance cost. No touch with flame in combustion section to avoid the asphalt degrade. Anti-abrasion & thermal-resistant flight, paddle and flexible chain to avoid RAP sticking. Intelligent inspection device with alarm monitoring and safety switch; FARO laser scanner assures precious system fitting for reliable operation.

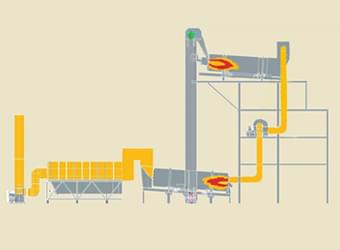

Fume treatment system

automatic cleaning for safetyWith thermal alarm and cut-off inspection switch at high temperature to avoid drum firing by duplicate protection; fan with thermal anti-rust and stick-free design, cooling gate joint control by synchronizing drum interior pressure operation, failure monitoring to activate alarm in real time to avoid any damage; Fume is redirected by the tube to the drum dryer at the new-asphalt plant for secondary combustion, since it is evenly distributed at the outlet of dryer, it won’t affect its normal operation.

Requirement customized

Maximize the efficiency by customized demandBased on the client’s actual need, NFLG provides the professional design of technical solution to boost the profitability for clients.