2277 Longyang Rd. Pudong, Shanghai, China info@mixingchina.com

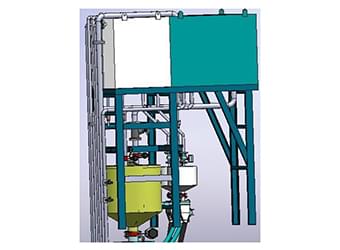

Silo on top concrete batch plant

- You are currently here!

- Home Product Concrete Mixing Plant Silo on top concrete batch plant

Silo on top concrete batch plant

NFLG silo is the highest installed concrete batching plant in Zhejiang, China

- Location: Zhejiang, China

- Model: HZS270

- Startup: 2019

- Equipment highlights: High production efficiency, energy conservation and environmental protection.

Silo on top concrete batch plant

Introduction& Advantages

Powder silo on top concrete batch plant developed by NFLG has advantages such as energy-saving, stability, environment-friendly, and intelligence. The model includes HZS180, HZS200 and HZS225. The biggest productivity reaches 225m³/h theoretically.

- Twin spiral mixer, short mixing time, under standard conditions, can save 15% of the mixing time.Under standard conditions, energy consumption can be saved by 20%.

- The whole plant is environmentally friendly design, built-in pulse dust collector, effectively reduce dust emissions, the main body of the plant is fully enclosed, green and environmentally friendly.

Parameters

| Model | HZS180 | HZS200 | HZS225 | |

|---|---|---|---|---|

| Theoretical productivity(m³/h) | 150 | 200 | 225 | |

| Mixer | Model | JS3000 | JS4000 | JS4500 |

| Discharge volume (L) | 3000L | 4500L | ||

| Aggregate size (mm) | ≤80mm | |||

| Batching station | Bin volume (m³) | 4 storehouses | ||

| Conveyor capacity of inclined belt conveyor(t/h) | 600t/h | 900t/h | ||

| Scale range & accuracy | Stone scale (kg) | (1200-3600)±2% | (1600-4800)±2% | (1800-5400)±2% |

| Sand scale (kg) | (800-2400)±2% | (1050-3200)±2% | (1200-3600)±2% | |

| Cement scale (kg) | (600-1800)±1% | (800-2400)±1% | (900-2700)±1% | |

| Fly ash scale (kg) | (200-600)±1% | (250-800)±1% | (300-900)±1% | |

| Water scale (kg) | (250-800)±1% | (400-1200)±1% | ||

| Additivescale (kg) | (25-80)±1% | (40-120)±1% | ||

| Dischargeheight (m) | 4.2m | |||

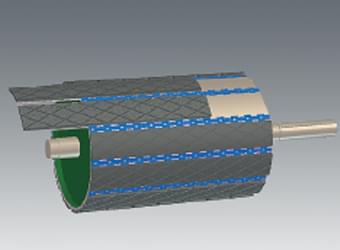

Conveying system

wear-resistant and durable, convenient maintenanceUsing replaceable friction disc type rubber roller, can be replaced within half an hour (Replacement of the old roller usually takes 4 days). Five cleanings + water cleaning to reduce belt abrasion.

Powder measurement system

scientific setting, accurate measurementThe scientific design of the overall measurement system structure avoids the adverse effects of the main tower and other factors on the powder scale, and it will not result to accumulated materials, pull scales, and drag scales to ensure the measurement accuracy.

Liquid metering system

intelligent adjustment and controllable qualityCoarse and precise measurement of liquid admixture, equipped with adjustment devices such as liquid storage bag and manual ball valve, automatically realizes the function of overweight deduction, missing supplement function, timely adjustment, and improves the accuracy of measurement. With admixture leak-proof device to ensure the quality of concrete.

Dust removal system

efficient dust removal, energy saving and consumption reductionUsing pulse bag filter, the dust removal efficiency is as high as 99.9%, and low maintenance costs. The large fan actively extracts and removes dust, which can balance the pressure of each system in the main tower to ensure measurement accuracy and material discharge speed.

Demand customization

according to customer needs, scientific designBased on the actual needs of customer projects, NFLG provides scientific production solution design to help enterprises achieve profitability.