2277 Longyang Rd. Pudong, Shanghai, China info@mixingchina.com

Twin Shaft Mixer

- You are currently here!

- Home Product Concrete Mixing Plant Twin Shaft Mixer

Twin Shaft Mixer

- Location: Jiangsu, China

- Model: JS7000

- Startup: 2019

- Equipment highlights: High production efficiency, the sealing effect is good, green and environmental protection

Twin Shaft Mixer

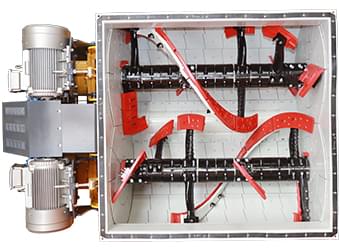

Introduction& Advantages

NFLG develops and manufactures a twin spiral continuous blade mixer (also known as a double horizontal shaft mixing host) which has a high circulating flow speed and has the advantages of powerful twisting flow and cutting and shearing effects. The concrete is mixed and kneaded faster, the workability is better, and the quality of the concrete is higher. At present, NFLG has three types of mixers with double horizontal shafts: twin spiral clean shaft, reinforced hydraulics, and prefabricated parts (single outlet, double outlet) mixer.

- The degree of intelligence is high, which can effectively improve the working efficiency of the equipment.

- The degree of intelligence is high, which can effectively improve the working efficiency of the equipment.

Parameters

| Model | Motor power(Kw) | A(mm) | B(mm) | C(mm) | D(mm) | E(mm) | F(mm) | weight(t) |

|---|---|---|---|---|---|---|---|---|

| JSL1000 | 2X22 | 2967 | 1530 | 1600 | 1570 | 2246 | 1780 | 6.7 |

| JSL1500 | 2X30 | 3187 | 1750 | 1820 | 1570 | 2246 | 1780 | 7.3 |

| JSL2000 | 2X37 | 3318 | 1650 | 1982 | 1700 | 2618 | 1790 | 9.8 |

| JSL2250 | 2X45 | 3318 | 1650 | 1982 | 1700 | 2618 | 1790 | 9.9 |

| JSL3000 | 2X55 | 3956 | 2300 | 2632 | 1700 | 2618 | 1820 | 11 |

| JSL3500 | 2X65 | 3956 | 2300 | 2632 | 1700 | 2618 | 1820 | 11.2 |

| JSL4000 | 2X75 | 4000 | 2210 | 2585 | 1820 | 2884 | 1990 | 13.2 |

| JSL4500 | 2X75 | 4240 | 2450 | 2825 | 1820 | 2884 | 1990 | 14 |

| JS 5000 | 2X90 | 4253 | 2430 | 2910 | 2175 | 3172 | – | 21 |

| JS 6000 | 4X65 | 6375 | 2960 | 3650 | 2180 | 3222 | – | 28 |

| JS 7000 | 4X75 | 7190 | 3240 | 3930 | 2180 | 3222 | – | 33 |

| JS 8000 | 4X90 | 7190 | 3240 | 3930 | 2180 | 3222 | – | 34 |

Mixing system

wear-resistant and durable, suitable for various aggregatesIt is suitable for mixing concrete aggregate with high compressive strength and strong abrasiveness. Equipped with overload protection measures in case of extra large diameter aggregates or iron parts, the adaptability to the maximum aggregate size reaches 150 ~ 180mm particle size, and can adapt to the oversize aggregates allowed according to the standard.

Intelligent monitoring system

multiple guarantees, efficient productionOnline real-time detection of concrete temperature and slump changes during mixing, control product quality, and eliminate inferior products. Equipped with centralized lubrication system monitoring and protection devices to provide sound and light indication and alarm for motor failure, oil circuit distributor failure, low oil level, etc. to ensure safe and stable production. The opening position of the discharge door is detected to realize automatic control of the discharge speed and improve the operation efficiency.