2277 Longyang Rd. Pudong, Shanghai, China info@mixingchina.com

RUBBER MILL LINERS

- You are currently here!

- Home Parts GRINDING MILL PARTS RUBBER MILL LINERS

AG | SAG | BALL MILL RUBBER MILL LINERS

The mill is the heart of mineral processing plant. Rubber mill linings have been used successfully in secondary and regrind milling applications and are specified today for these applications.

However with the support of improved materials and computer aided design programs, rubber mill liners are being used more and more in primary grinding applications as well.

In addition to its abrasion resistance, it is also resistant to most chemicals. With long experience of development and manufacture of rubber mill liners, NFLG is able to offer you the superior design and excellent product that ensures optimal grinding and lining performance.

RUBBER MILL LINERS

Why Choose NFLG Rubber Mill Liners?

① Lower Cost: Our rubber mill liners are relatively cost effective as “cost per ton of ore grind” is lower;

② Longer Life: Our rubber mill linings have “longer operational life”;

③ Less Maintenance: Rubber mill liners are engineered to resist abrasion, increasing the maintenance interval;

④ Faster/ Safer: Rubber mill components are lighter in weight and easier to handle when changing;

⑤ Reduced Noise Level: Rubber Mill Liners reduce the noise level to safer levels by absorbing impact against the shell.

⑥ Reduced Weight: Rubber Liners are only about 1/8 by weight of metallic liners of same size.

⑦ No Leakage or Peening: Rubber mill liners seal to the shell eliminating slurry leakage from the mill.

⑧ Reduced Power Consumption: Light weight of Rubber Linings reduce the current draw of the mill.

Available Rubber Mill Liners

NFLG provides all components of mill liners made of wear-resistant rubber, including: Trunnion & Bell Mouth Liners, Feed End(FE) Liners, Lifter Bars or Shell Lifter, Discharge End(DE) Liners, Grate Plates and Trommel.

NFLG has considerable experience in designing and producing linings for different types of grinding mills, including:

- Autogenous(AG) mills

- Semi-autogenous(SAG) mills

- Rod mills

- Ball mills

- Peddle mills

- FGD mills

- Continuous mills

- Batch grinding mills

- Scrubber and washing drums

Accessories

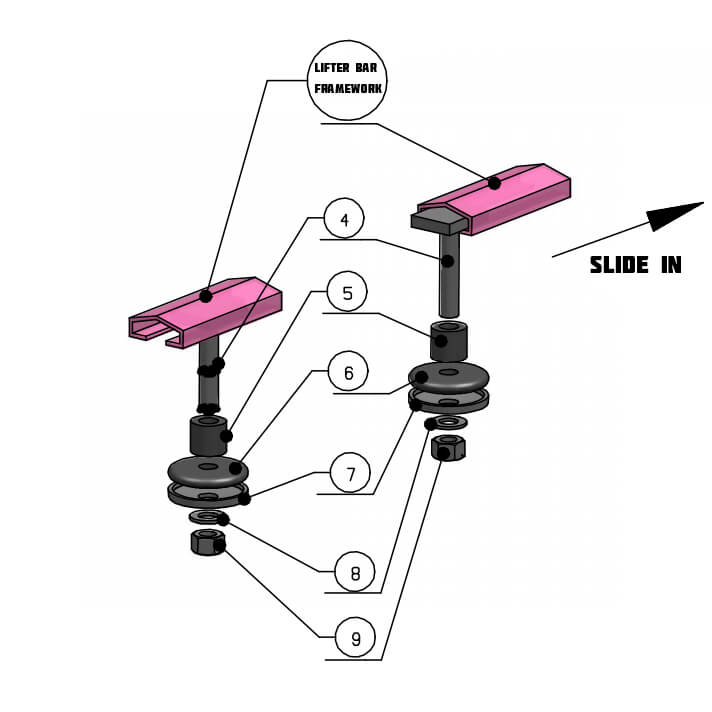

NFLG™ mill liners adopts easy installation T-shaped screw fixing accessories, which includes: ④ T-shape Screw; ⑤ Rubber Bushing; ⑥ Rubber Sealer; ⑦ Cup Washer; ⑧ Washer; ⑨ Nut;

T-shape screw can be slided inside the liner framework to fit the existing bolt hole position. NFLG™ easy installation accessories provides good sealing performance and make the liner replacing more efficient.

Custom Rubber Mill Liners by NFLG MINING®

NFLG has developed grades of wear resistance rubber for specific operating conditions in all types of mills.

Our rubber lifter bars will utilize your current bolt hole spacing, this eliminates the need to drill new attachment holes. All of the rubber components are tailor made to meet your specific mill and operating conditions.

You are welcome to contact our experts with drawings or any special requirements.