2277 Longyang Rd. Pudong, Shanghai, China info@mixingchina.com

METAL MATRIX CERAMIC BLOW BARS

- You are currently here!

- Home Parts IMPACT CRUSHER PARTS METAL MATRIX CERAMIC BLOW BARS

CERAMIC BLOW BARS

Metal Matrix Composites (MMC) Ceramic Blow Bars also known as Cearmic Blow Bars, include:

- Chrome Iron Matrix with Ceramic Composites Blow Bars;

- Martensitic Alloy Steel Matrix with Ceramic Composites Blow Bars;

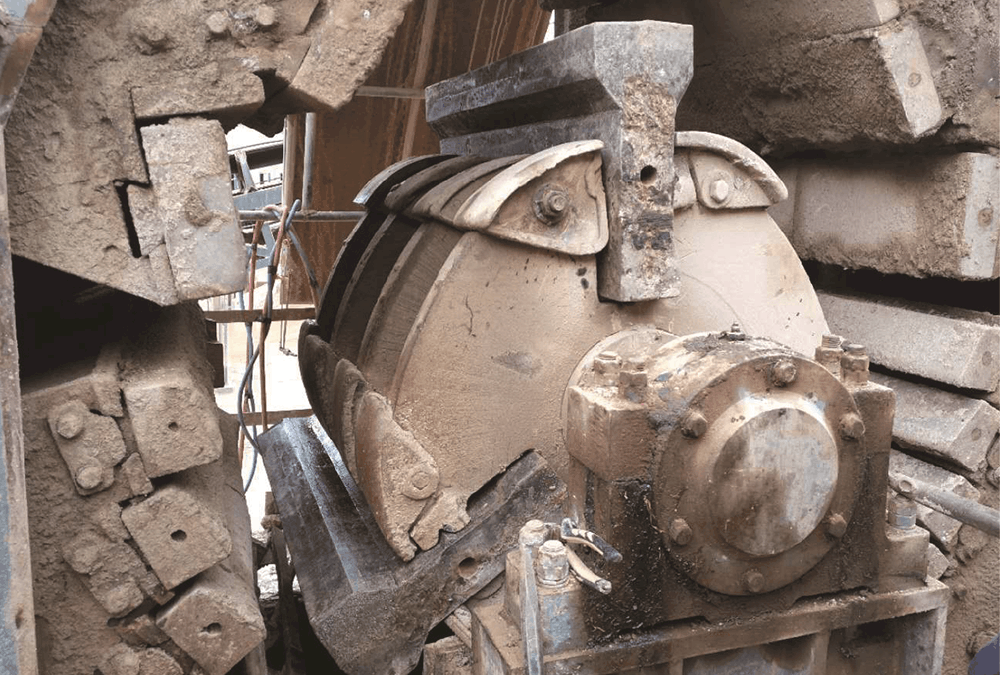

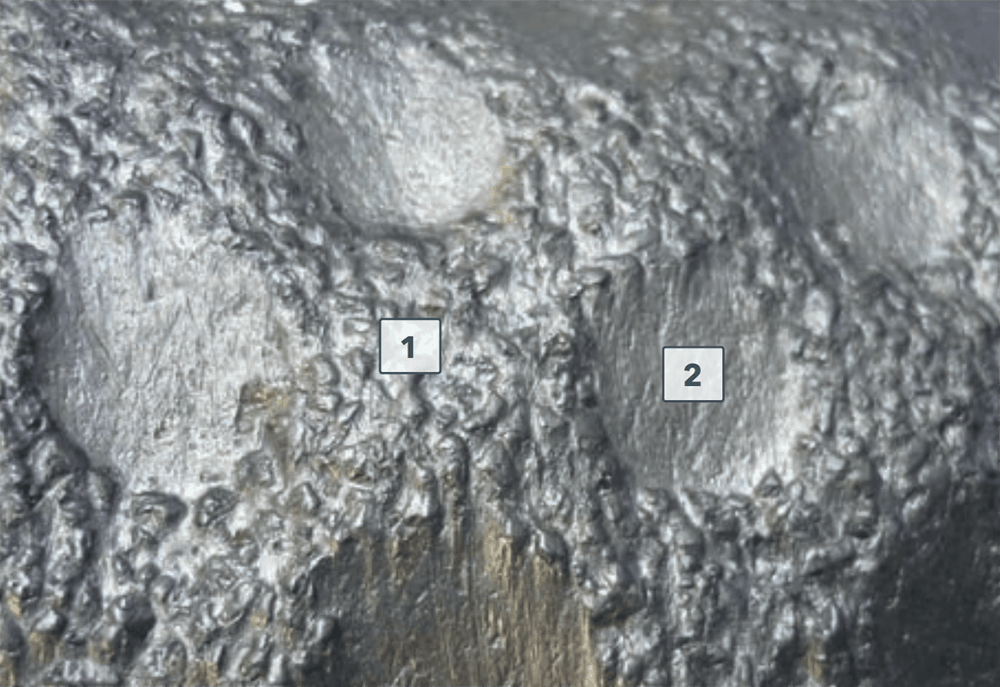

Ceramic Blow Bar is one of the most common impact crusher wear parts. It combines the high resistance of the metal matrix with extremely hard ceramics. Porous preforms made of ceramic particles are produced in the process. The metallic molten mass penetrates into the porous ceramic network.

METAL MATRIX CERAMIC BLOW BARS

Why Choose NFLG™ Ceramic Blow Bars?

① We offer OEM interchangeable impact crusher parts & liners;

② Wear-Resistant but Impact-Resistant at the same time;

③ We have rich experience and knowledge in the casting process;

④ We extend the service life of the impact crusher liners;

⑤ We provide more reasonable and competeable prices;

⑥ We provide more professional services and suggestions.

Metallurgy of the Metal Matrix Ceramic Blow Bars

The combination of metal matrix and extremely hard ceramics makes the blow bars especially wear-resistant but at the same time very impact-resistant. With blow bars made of composites from the field of ceramics, a service life that is three to five times as long as that of martensitic steel can be achieved.

Martensitic Alloy Steel Matrix + Ceramic Composites

Martensitic alloy steel with ceramic is a premium composite metallic matrix steel with hard ceramic alloy inserts on the wear surface. The hard alloy ceramics combined with martensitic steel matrix provides a significant working life advantage over standard martensitic steel blow bars.

- This material is commonly used in recycling industries and primary crushing in quarries. Certain applications are unsuitable for this material, including limestone crushing and slag recycling.

- E.g. primary crushing of sandstone mine, construction waste recycling, concrete, natural stone.

Chrome Iron Matrix + Ceramic Composites

Chrome Iron with ceramic is a premium composite metallic matrix iron with hard ceramic alloy inserts on the wear surface. The hard alloy ceramics combined with either medium chrome or high chrome iron matrix provides a significant working life advantage over standard chrome iron bars.

- Whilst this material can be very successful in secondary applications, it should not be used for primary crushing or very hard and abrasive applications.

- E.g. secondary & tertiary crushing of sandstone mine, pre-crushed concrete, asphalt recycling (metal-free), metal ore crushing, etc.

Genuine Alternative Spare Parts – Ceramic Blow Bars Made by NFLG MINING®

NFLG® offers different designs and manufactures various solutions of blow bar for an extensive range of OEM horizontal impact crusher brands including: Hazemag, Mesto, Kleeman, Rockster, Rubble Master, Powerscreen, Striker, Keestrack, McClosky, Eagle, Tesab, Finlay and others.

NFLG® “Genuine Alternative” blow bars are designed to extend wear life, provide a perfect interchangeable fitting for your impactor, and increase production rates while decreasing costs-per-ton.

Notice: The following table does not include all the accessories that we can produce. If you need bars from other brands, or know the OEM serial number of the blow bars that you are looking to replace, or can provide the drawing of the bars that you need to customize, please feel free to contact us by email or call.

Models

| Nordberg NP Series | Lokotrack LT Series | KLEEMANN | ROCKSTER |

|---|---|---|---|

| NP1313 NP1415 NP1620 NP2023 NP1110 BP13 NP15 NP20 | LT1110 LT1213 LT1213S LT1315 Nordtrack I908S | MR 110 Z EVO2 MR 122 Z MR 130 Z EVO2 MR 150 Z MR 170 Z MF 14 S MF 16 S | R700S R900 R1000S R1100S R1100DS |

| Finlay | Striker | TESAB | McCloskey |

| I-140 I-140RS I-120 I-120RS IC-110 IC-110RS IC-100 IC-100RS | HQ907 HQ910 HQ1112 HQ1312 HQR907 HQR910 HQR1112 HQR1312 | 623CT 1012T 1012TS 1412T | I44v3 I44Rv3 I54v3 I54Rv3 I34 I34R |

| HAZEMAG HPI-H Series | HAZEMAG HPC Series | HAZEMAG HSI Series | HTI Series |

| HPI-H 1010 HPI-H 1214 HPI-H 1414 HPI-H 1615 HPI-H 1618 | HPC-1414 HPC-1615 HPC-1618 HPC-1622 HPC-1822 HPC-2022 HPC-2025 HPC-2030 | HSI 1007 HSI 1010 HSI 1014 HSI 1414 HSI 1420 HSI 1625 HSI 1630 | HTI 1005 HTI 1010 HTI 1014 |

| HAZEMAG HPI Series | Eagle Crusher | RUBBLE MASTER | POWERSCREEN |

| HPI-1622 HPI-1822 HPI-2022 HPI-2025 HPI-2030 HPI-2225* HPI-2230 HPI-2530 | UM-04 UM-05 UM-15 UM-25 UM-45 UM-69 | RM 60 RM 70GO! 2.0 RM 90GO! RM 100GO! RM 120GO! RM V550GO! | TRAKPACTOR 230 TRAKPACTOR 230SR TRAKPACTOR 320 & 320SR TRAKPACTOR 550 TRAKPACTOR 550SR |