NFLG® JAW CRUSHER PARTS

Jaw Crushers are mainly used as primary crushers and secondary crushers in mining, construction materials, infrastructure and other sectors.

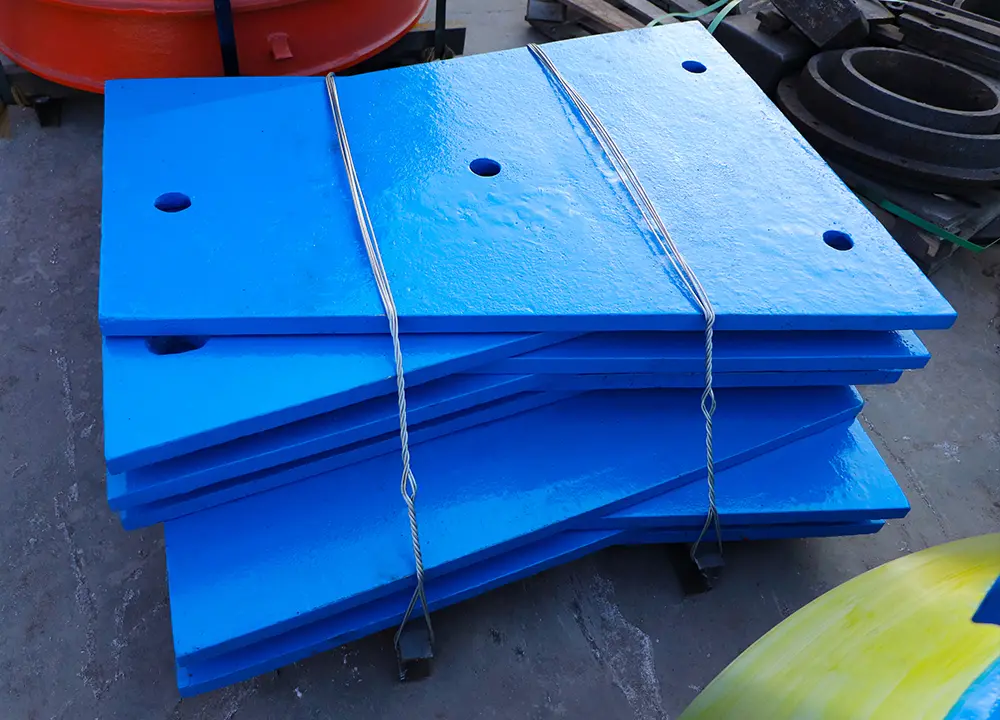

As a popular crusher, the main working parts of the jaw crusher are two jaw plates.

- One is called the fixed jaw (stationary jaw), which is fixed vertically on the front wall of the machine frame.

- The other one is called the movable jaw (swing jaw), its position is inclined, and it forms a crushing chamber (working chamber) with the fixed jaw, which is big at feeding and small at discharging.

Then since the movable jaw plate periodically reciprocates against the fixed jaw plate, the material will be crushed by squeezing, bending and splitting.

Therefore, the jaw dies and the cheek plates are the most common wearing jaw crusher parts. We can produce jaw plates with different tooth shapes and materials according to the your working conditions. Our cast cheek plates are made from 13% Manganese and 2% chrome iron. Our crusher jaws are cast from 18% manganese 3% chrome iron.

We are also able to custom design jaws that offer increased performance by using ultra heavy duty 21% manganese and 2% chrome iron, and 24% manganese and 3% chrome iron.

Special heat treatment methods are used to make each jaw crusher liner have a higher degree of wear resistance and service life. According to customer feedback, the service life of HF jaw crusher parts is 20-30% longer than ordinary parts.

Manganese Liners for Jaw Crusher

The the jaw plates and the cheek plates are the most common replacement parts on a jaw crusher. NFLG™ can produce jaw plates with different tooth shapes and materials according to the your application.

Our cheek plates are start from 13% Manganese with 2% chrome iron (Mn13Cr2). And our standard crusher jaws range from Mn13Cr2, Mn18Cr2 to Mn22Cr2. Some special designs, such as metal insert, adding molybdenum to extend wear life… can be made on requirements.

Special heat treatment methods are used to make each jaw crusher liner have a higher degree of wear resistance. According to our customer’s feedback, the service life of NFLG™ jaw crusher parts is 20-30% longer other supplier’s.

NFLG® Genuine Alternative Jaw Crusher Spare Parts

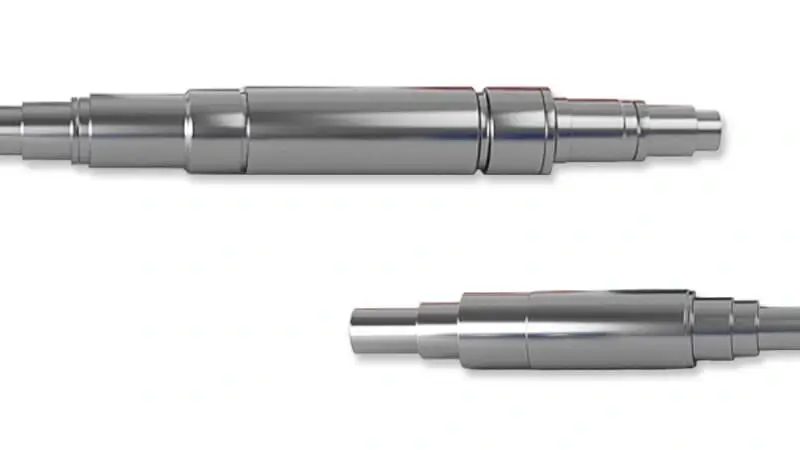

NFLG also manufacture and stock precision-machined eccentric shafts, labyrinths, spacers and end covers for most popular jaw crushers.

Other parts such as toggle assembly, pitman assembly, fasten kits and frames are also in our scope of supply.

All NFLG™ compatible crusher parts are manufactured and warranted by NFLG®, for the avoidance of doubt it is not implied that our branded parts originate from the OEM.

Common jaw crusher spares in our scope of supply:

- Frame

- Pitman

- Eccentric Shaft

- Toggle Plate

- Toggle Seat

- Cheek Plate

- Pulley

- Labyrinth Seal

- Flywheel

- Bearing House

- Side Plate

- Front End

- Tension Rod

- Tightening Bushing

- Find more in our database

Most Popular Jaw Crusher Parts

JAW PLATES

Jaw plates are divided into fixed jaw plates and movable jaw plates, which are the most in demand wear parts in jaw crushers.

ECCENTRIC SHAFTS

The eccentric shaft is one of the key component that generate the crushing action on a jaw crusher.

PITMAN

The pitman achieves its movement through the rotation of the eccentric shaft, it is the key component to form the crushing chamber.

Your Trusted Jaw Crusher Parts Supplier

Contact Us Today

NFLG MINING™ aftermarket jaw crusher replacement parts and wear parts are used by crusher operators worldwide and are often specified by many of the world’s most prestigious mining, quarrying, demolition and recycling operators together with several of the major original equipment manufacturers.